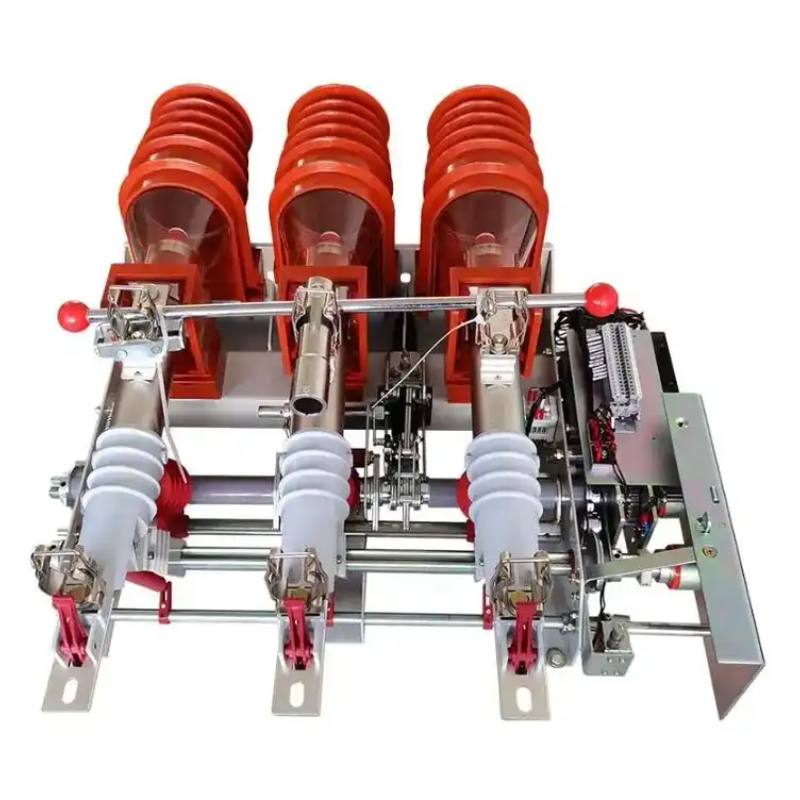

China Load break switch FKRN12-12D/T Manufacturers, Suppliers, Factory

China Load break switch FKRN12-12D/T is one kind of products from RZMV factory. As one of leading manufacturers and suppliers in China, we provide durable products. We can sell them at a low price and can be customized. We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

Through-core current transformer indoor high current transformer for Inflatable Cabinet

LMZC-10 Current Transformer - Accurate and Reliable Solution for Current Monitoring and Protection in Power Systems The LMZC-10 Current Transformer is an exceptional device designed for precise and reliable current measurement in AC circuits. Its innovative design and advanced technology make it an ideal choice for accurate current monitoring and protection in various power systems. At the heart of the LMZC-10 is a primary coil and a secondary coil. The primary coil consists of a specific number of turns and is connected within the measurement circuit. When an AC current flows through the primary coil, it generates an alternating magnetic field around it. This magnetic field, in turn, induces an electromotive force within the secondary coil. The secondary coil is wound around the primary coil, with fewer turns than the primary coil, to ensure proportional voltage output. To maintain a stable voltage output within an appropriate range, the LMZC-10 is equipped with a compensating coil. The compensating coil has the same number of turns as the secondary coil but with a reversed winding direction. This ingenious design ensures that the induced potential in the compensating coil counteracts the induced potential in the secondary coil, resulting in a stable and accurate output voltage. The output voltage from the secondary coil is then connected to a load circuit, which generates a voltage signal proportional to the current in the primary coil. By measuring this output voltage, the magnitude of the current in the primary coil can be accurately determined. This makes the LMZC-10 an invaluable tool for current monitoring and protection in power systems. The LMZC-10 Current Transformer offers numerous advantages. Its precise measurements provide accurate data for load management and fault analysis, allowing operators to make informed decisions regarding the power system. As a key component in electrical protection systems, the LMZC-10 ensures the safety and reliability of the entire system by enabling quick and accurate detection of abnormal currents or faults. In conclusion, the LMZC-10 Current Transformer offers a reliable and accurate solution for current measurement in AC circuits. Its primary and secondary coils, along with the compensating coil, work in harmony to provide stable voltage output and precise current measurements. With its advanced features and exceptional performance, the LMZC-10 is widely used in power systems for current monitoring and protection applications. Trust the LMZC-10 to deliver accurate and reliable results for your current measurement needs, ensuring the efficiency and safety of your electrical systems.Indoor high voltage vacuum circuit breaker

The ZN85-40.5 KV indoor high voltage vacuum circuit breaker is a switch device used for interrupting high voltage electrical circuits in terms of working current and fault current. It features an integrated and modular design with a simple and reasonable overall structure. The breaker is arranged in an upper and lower configuration, with the arc-extinguishing compartment located on top and the interlocking and operating mechanisms below. The device utilizes the specialized 3AV3 spring operating mechanism, which does not require adjustment and ensures stable and reliable operation. The vacuum arc-extinguishing compartment is enclosed within an insulated cylinder, thereby enhancing insulation performance and reducing overall dimensions. This series of ZN85-40.5 KV circuit breakers is suitable for indoor installation in devices rated at 40.5 KV and 50 Hz. It is equipped with the dedicated 3AV3 spring mechanism. The breaker can be installed in the JYN1-40.5(Z) removable metal-enclosed switchgear or the KYN61-40.5(Z) assembled metal-enclosed switchgear. It is considered the ideal circuit breaker for 40.5 KV installations. This series of products boasts high technical parameters, strong breaking capacity, reliable operation, stable performance, long service life, and easy maintenance. Furthermore, it is safe and free from explosion risks or pollution. It is widely used for protection and control of single busbar electrical facilities in industrial and mining enterprises, power plants, and substations. It is also suitable for frequent operations and special scenarios such as the switching of complete capacitor banks. The ZN85-40.5 KV indoor high voltage vacuum circuit breaker combines advanced design, excellent performance, and reliability to meet the demanding requirements of high voltage electrical circuit operations.High Voltage Reactive Power Compensation Device

Rongzhi Electric Power is a large-scale High Voltage Reactive Power Compensation Device manufacturer and supplier in China. We have been specialized in High voltage equipment for many years. Our products have a good price advantage and cover most of the South America, Middle East, Africa, Southeast Asia markets. We look forward to becoming your long-term partner in China.High Voltage Indoor 50Hz Vacuum Circuit Breaker

Introducing the ZN28-12 series indoor high-voltage vacuum circuit breaker, a cutting-edge solution designed to optimize electrical performance and ensure efficient power distribution. This circuit breaker is equipped with a middle-sealed longitudinal magnetic field vacuum arc extinguisher and a new operating mechanism, guaranteeing reliable and safe operations. The operating mechanism and the vacuum arc extinguishing chamber adopt a front and rear layout, providing enhanced control and functionality. By connecting the operating mechanism to the movable conductive rod of the vacuum arc-extinguishing chamber through an insulating pull rod, it drives the movable contacts of the chamber to execute seamless opening and closing movements according to specified mechanical parameters. This precise movement enables the breaker to effectively break short-circuit currents and improves the mechanical life of the arc extinguishing chamber. To further enhance the circuit breaker's performance during operation, an auxiliary guide device is installed on the upper bracket of the fixed arc extinguishing chamber. This device ensures that the moving contacts remain well aligned during the opening and closing process, preventing any potential disruptions and enhancing the overall efficiency of the breaker. This innovation not only improves the short-circuit current breaking capability but also extends the lifespan of the arc extinguishing chamber. One of the key features of this series is the centrally enclosed longitudinal magnetic field vacuum arc extinguishing chamber. When the moving and static contacts open under load, the vacuum arc burns in the contact gap. However, the arc is swiftly extinguished when it crosses zero. The special structure of the contact generates a significant longitudinal magnetic field during arcing. This magnetic field evenly distributes the arc on the contact surface, resulting in a low arc voltage. Through this innovative design, the circuit breaker achieves a high arc voltage dielectric strength recovery speed. This unique characteristic significantly reduces the arc energy and electrical corrosion rate, ultimately improving the short-circuit current breaking capability and enhancing the overall lifespan of the circuit breaker. The ZN28-12 series indoor high-voltage vacuum circuit breaker is a reliable and efficient solution for various electrical systems. With its advanced features and superior performance, it plays a vital role in maintaining the stability and safety of power distribution networks. Trust in the ZN28-12 series to deliver exceptional results for your electrical needs.Single Phase High Current Residual Zero Sequence Current Transformer

LMZK Series Current Transformer is a compact and lightweight device known for its small size, easy installation, and convenient functionality. It is widely used in compact fully insulated ring main units and is highly compatible with remote terminal devices like RTUs and FTUs, providing essential data support for the entire system. The installation process is simple and efficient, as it can be directly attached to the connected input and output cables. This current transformer has found extensive applications in various models of compact fully insulated ring main units, including SafeRing/Plus, Uniswitch, RM6/SM6, SVS, GA/GE, FB, and SS. Additionally, it is also suitable for use in combination substations and cable junction boxes. The LMZK Series Current Transformer utilizes high-quality imported silicon steel sheets with high magnetic permeability as its magnetic core material. This unique choice ensures that the core can be divided and offers minimal magnetic flux loss. The half-ring-shaped core and secondary winding are encapsulated in high-quality epoxy resin under vacuum in a flame-retardant plastic casing. This design not only guarantees moisture resistance but also provides stable and maintenance-free performance. During installation, the two half-ring cores are securely clamped onto the phase-separated cables using durable stainless steel brackets. This integration with the cables creates a harmonious and aesthetically pleasing appearance. The LMZK Series Current Transformer is compatible with 10KV cables ranging from 35mm2 to 400mm2, and the stainless steel brackets are resistance-free and ensure a reliable and robust connection. In summary, the LMZK Series Current Transformer stands out due to its compact size, lightweight nature, easy installation, and compatibility with various remote terminal devices. Its high-quality materials and superior design contribute to its exceptional performance in fully insulated ring main units, combination substations, and cable junction boxes.12KV 24kv 40.5KV Box Type Fixed AC Metal Enclosed Switchgear

XGN15-12/24/40.5 unit type air insulated ring main unit with SF6 load switch as main switch, for whole cabinet is suitable for electric distribution automation and compact also expandable metal close switchgear. It characters in its simple structure, flexible operation, reliable interlocking and convenient installation etc.,. It can take self-produced FLS-12/24 load break switch; also according to user’s demand can be assembled with the internationally top-ranking brand LBS or VCB, Operational methods for the main switch inside ring main unit can be either manual or electric power driven. It can meet the requirement of “Four Controls” when matched with FTU and RTU. In accordance with the national standard GB3906 and international standardIEC298, protection degreeIP2X.